|

|

|

|

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Hi all,

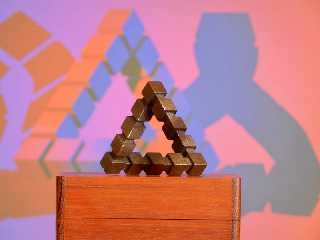

A typical way of using with POV-Ray is the following. You take something from

the real world, say, a hammer that you really like, and model it in POV-Ray.

Subsequently, you use the model to create one or more images. You can, however,

also go in the opposite direction. Model an object in POV-Ray, and use that

model to realize the object in the real world, for example via 3D printing.

I recently did this, and the attached image shows the result. To be absolutely

clear, before anyone starts complimenting me on my wood and metal texturing

skills, the image is a photograph. It is not a render.

The image shows a 3D-printed object, which when viewed from the right direction

looks like an impossible triangle. It has been printed in stainless steel, with

a Bronze Plate finish. In the background you see an image created by POV-Ray.

Both the 3D-printed object and the background image were created from the same

POV-Ray based model. Custom macros were used to calculate each point in the

mesh. Parameters control amongst others the granularity of the mesh and the

number of cubes in the model. To convert the model to a format suitable for

3D-printing, the mesh was exported to file and further processed via MeshLab and

Sketchup.

I have put the object up for sale at Shapeways [1]. I am curious to see if there

will be any takers, but not getting my hopes up too high.

Kind regards,

Erwin

[1] https://www.shapeways.com/shops/eriban

Post a reply to this message

Attachments:

Download 'dscn0101a.jpg' (110 KB)

Preview of image 'dscn0101a.jpg'

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

On Sun, 21 Jul 2013 15:42:04 +0200, Eriban

<pov### [at] spamgourmet com> wrote:

> Hi all,

>

> A typical way of using with POV-Ray is the following. You take something

> from

> the real world, say, a hammer that you really like, and model it in

> POV-Ray.

> Subsequently, you use the model to create one or more images. You can,

> however,

> also go in the opposite direction. Model an object in POV-Ray, and use

> that

> model to realize the object in the real world, for example via 3D

> printing.

>

> I recently did this, and the attached image shows the result. To be

> absolutely

> clear, before anyone starts complimenting me on my wood and metal

> texturing

> skills, the image is a photograph. It is not a render.

>

> The image shows a 3D-printed object, which when viewed from the right

> direction

> looks like an impossible triangle. It has been printed in stainless

> steel, with

> a Bronze Plate finish. In the background you see an image created by

> POV-Ray.

>

> Both the 3D-printed object and the background image were created from

> the same

> POV-Ray based model. Custom macros were used to calculate each point in

> the

> mesh. Parameters control amongst others the granularity of the mesh and

> the

> number of cubes in the model. To convert the model to a format suitable

> for

> 3D-printing, the mesh was exported to file and further processed via

> MeshLab and

> Sketchup.

>

> I have put the object up for sale at Shapeways [1]. I am curious to see

> if there

> will be any takers, but not getting my hopes up too high.

>

> Kind regards,

> Erwin

>

> [1] https://www.shapeways.com/shops/eriban

>

>

>

Cool!

--

-Nekar Xenos- com> wrote:

> Hi all,

>

> A typical way of using with POV-Ray is the following. You take something

> from

> the real world, say, a hammer that you really like, and model it in

> POV-Ray.

> Subsequently, you use the model to create one or more images. You can,

> however,

> also go in the opposite direction. Model an object in POV-Ray, and use

> that

> model to realize the object in the real world, for example via 3D

> printing.

>

> I recently did this, and the attached image shows the result. To be

> absolutely

> clear, before anyone starts complimenting me on my wood and metal

> texturing

> skills, the image is a photograph. It is not a render.

>

> The image shows a 3D-printed object, which when viewed from the right

> direction

> looks like an impossible triangle. It has been printed in stainless

> steel, with

> a Bronze Plate finish. In the background you see an image created by

> POV-Ray.

>

> Both the 3D-printed object and the background image were created from

> the same

> POV-Ray based model. Custom macros were used to calculate each point in

> the

> mesh. Parameters control amongst others the granularity of the mesh and

> the

> number of cubes in the model. To convert the model to a format suitable

> for

> 3D-printing, the mesh was exported to file and further processed via

> MeshLab and

> Sketchup.

>

> I have put the object up for sale at Shapeways [1]. I am curious to see

> if there

> will be any takers, but not getting my hopes up too high.

>

> Kind regards,

> Erwin

>

> [1] https://www.shapeways.com/shops/eriban

>

>

>

Cool!

--

-Nekar Xenos-

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

nice work!

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Very nice indeed.

Question:

> The image shows a 3D-printed object, which when viewed from the right direction

> looks like an impossible triangle. It has been printed in stainless steel, with

> a Bronze Plate finish. In the background you see an image created by POV-Ray.

/printed in stainless steel/ ?? I think you mean something else than I

do read... :-)

Thomas

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Am 22.07.2013 09:00, schrieb Thomas de Groot:

> Very nice indeed.

>

> Question:

>> The image shows a 3D-printed object, which when viewed from the right

>> direction

>> looks like an impossible triangle. It has been printed in stainless

>> steel, with

>> a Bronze Plate finish. In the background you see an image created by

>> POV-Ray.

>

> /printed in stainless steel/ ?? I think you mean something else than I

> do read... :-)

That's the marvels of modern 3D printing.

AFAIK shapeways actually print a wax model, and then die-cast it in

bronze steel; but there are 3D printers out there that work directly

with bare metal, using either sintering or depositing processes.

You can also get your stainless steel with a gold plating, and solid

sterling silver is another option (they do use some direct process for

the latter). Or how about glazed ceramic?

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

On 22-7-2013 10:09, clipka wrote:

> That's the marvels of modern 3D printing.

>

> AFAIK shapeways actually print a wax model, and then die-cast it in

> bronze steel; but there are 3D printers out there that work directly

> with bare metal, using either sintering or depositing processes.

>

> You can also get your stainless steel with a gold plating, and solid

> sterling silver is another option (they do use some direct process for

> the latter). Or how about glazed ceramic?

>

Really? I thought it went through a casting process... But then of

course, I have not been following closely the developments of the

technique.

Thomas

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

On 07/22/2013 07:27 AM, Thomas de Groot wrote:

> On 22-7-2013 10:09, clipka wrote:

>

>

>> That's the marvels of modern 3D printing.

>>

>> AFAIK shapeways actually print a wax model, and then die-cast it in

>> bronze steel; but there are 3D printers out there that work directly

>> with bare metal, using either sintering or depositing processes.

>>

>> You can also get your stainless steel with a gold plating, and solid

>> sterling silver is another option (they do use some direct process for

>> the latter). Or how about glazed ceramic?

>>

>

> Really? I thought it went through a casting process... But then of

> course, I have not been following closely the developments of the

> technique.

>

> Thomas

all kinds of things can be 3D printed now-a-days :

http://www.youtube.com/watch?v=82t84VIwlTE

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

> /printed in stainless steel/ ?? I think you mean something else than I

> do read... :-)

Google "DMLS" - most rapid prototyping houses will do it, our local one

does.

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Thomas de Groot <tho### [at] degroot org> wrote:

> On 22-7-2013 10:09, clipka wrote:

> > That's the marvels of modern 3D printing.

> >

> > AFAIK shapeways actually print a wax model, and then die-cast it in

> > bronze steel; but there are 3D printers out there that work directly

> > with bare metal, using either sintering or depositing processes.

>

> Really? I thought it went through a casting process... But then of

> course, I have not been following closely the developments of the

> technique.

>

> Thomas

For creating objects from stainless steel, Shapeways actually does not use a

die-cast either. As far as I understand it, glue is printed on thin layers of

metal powder, which results in a fragile structure. This then is post-processed

into a strong metal object. I assume by first removing unused powder and next

hardening it, presumably by applying heat, but now I am just guessing. Some

details can be found here: https://www.shapeways.com/materials/steel

Anyway, I find it fascinating that you can model something from your own home,

and have it subsequently realized in 3D, in a whole range of materials. This was

the first object I had printed in stainless steel, but I have used 3D printing

before to prototype a puzzle I designed. At that time, I used a cheaper, plastic

material. Cool stuff.

Erwin org> wrote:

> On 22-7-2013 10:09, clipka wrote:

> > That's the marvels of modern 3D printing.

> >

> > AFAIK shapeways actually print a wax model, and then die-cast it in

> > bronze steel; but there are 3D printers out there that work directly

> > with bare metal, using either sintering or depositing processes.

>

> Really? I thought it went through a casting process... But then of

> course, I have not been following closely the developments of the

> technique.

>

> Thomas

For creating objects from stainless steel, Shapeways actually does not use a

die-cast either. As far as I understand it, glue is printed on thin layers of

metal powder, which results in a fragile structure. This then is post-processed

into a strong metal object. I assume by first removing unused powder and next

hardening it, presumably by applying heat, but now I am just guessing. Some

details can be found here: https://www.shapeways.com/materials/steel

Anyway, I find it fascinating that you can model something from your own home,

and have it subsequently realized in 3D, in a whole range of materials. This was

the first object I had printed in stainless steel, but I have used 3D printing

before to prototype a puzzle I designed. At that time, I used a cheaper, plastic

material. Cool stuff.

Erwin

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

On 22-7-2013 15:21, scott wrote:

>> /printed in stainless steel/ ?? I think you mean something else than I

>> do read... :-)

>

> Google "DMLS" - most rapid prototyping houses will do it, our local one

> does.

>

I am showing my age... ;-)

Thomas

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|

|

![]()