|

|

|

|

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

A bit late for the sword of the week award, but this is

the result of the weekend's work.

Blade done in sPatch, guard is the intersection of a

cylinder and a heightfield and the hilt is CSG of

3 cylinders and 6 boxes.

Gail

--

*******************************************************************

* gsh### [at] monotix co co za * ERROR: COFFEE.COM not found *

* http://www.rucus.ru.ac.za/~gail/ * Insert cup and press any key *

*******************************************************************

My Software never has bugs, It just develops random features

******************************************************************* za * ERROR: COFFEE.COM not found *

* http://www.rucus.ru.ac.za/~gail/ * Insert cup and press any key *

*******************************************************************

My Software never has bugs, It just develops random features

*******************************************************************

Post a reply to this message

Attachments:

Download 'Sword.jpg' (13 KB)

Preview of image 'Sword.jpg'

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Gail Shaw wrote:

>

> A bit late for the sword of the week award, but this is

> the result of the weekend's work.

>

> Blade done in sPatch, guard is the intersection of a

> cylinder and a heightfield and the hilt is CSG of

> 3 cylinders and 6 boxes.

>

> Gail

> --

> *******************************************************************

> * gsh### [at] monotix co co za * ERROR: COFFEE.COM not found *

> * http://www.rucus.ru.ac.za/~gail/ * Insert cup and press any key *

> *******************************************************************

> My Software never has bugs, It just develops random features

> *******************************************************************

>

> [Image]

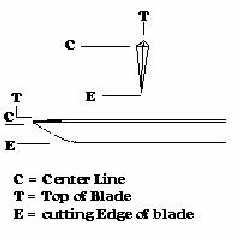

It has a wicked look to it. The metallic finish is off a little but one

could let that go if they were on the wrong end of that point. Seriously

though it is a little too white and could use a little more of a silver

glint to it.

Personally I would bring the final curve at the tip up a little more

abruptly than it currently is and counter sharpen the top of the blade

for about 1/2 to 3/4 of an inch from the tip back towards the hilt.

See my poor diagram for an example.

This will give the blade two cutting edges at the tip for extra

penetrating power plus it adds structural strength to the tip region.

It also keeps the point from abruptly ending at a flat squared surface

which puts to much reliance on a thin unsupported edge. The counter

bevel relieves this by creating "V" shapes back to back forming a

diamond shape which is stronger than a pyramid or 3 point wedge shape.

Once initial penetration of the victim is achieved the single cutting

edge can finish without the aid of the four surface point. It is a common

arrangement with long knives and fine blades such as this and is hardly

noticeable from a distance. It is quite noticeable without it. It looks

nicely wicked as is but the shape of the tip offers poor utility and would

break easily if used for anything more the ceremonial dress or slicing

sausage and bread for dinner. If I had a scanner I would scan in some

images from a sworders catalogue I have here that shows the common blade

shapes and points for swords of this type. Maybe in a couple of months

I'll have one on line (sigh).

--

Ken Tyler

mailto://tylereng@pacbell.net za * ERROR: COFFEE.COM not found *

> * http://www.rucus.ru.ac.za/~gail/ * Insert cup and press any key *

> *******************************************************************

> My Software never has bugs, It just develops random features

> *******************************************************************

>

> [Image]

It has a wicked look to it. The metallic finish is off a little but one

could let that go if they were on the wrong end of that point. Seriously

though it is a little too white and could use a little more of a silver

glint to it.

Personally I would bring the final curve at the tip up a little more

abruptly than it currently is and counter sharpen the top of the blade

for about 1/2 to 3/4 of an inch from the tip back towards the hilt.

See my poor diagram for an example.

This will give the blade two cutting edges at the tip for extra

penetrating power plus it adds structural strength to the tip region.

It also keeps the point from abruptly ending at a flat squared surface

which puts to much reliance on a thin unsupported edge. The counter

bevel relieves this by creating "V" shapes back to back forming a

diamond shape which is stronger than a pyramid or 3 point wedge shape.

Once initial penetration of the victim is achieved the single cutting

edge can finish without the aid of the four surface point. It is a common

arrangement with long knives and fine blades such as this and is hardly

noticeable from a distance. It is quite noticeable without it. It looks

nicely wicked as is but the shape of the tip offers poor utility and would

break easily if used for anything more the ceremonial dress or slicing

sausage and bread for dinner. If I had a scanner I would scan in some

images from a sworders catalogue I have here that shows the common blade

shapes and points for swords of this type. Maybe in a couple of months

I'll have one on line (sigh).

--

Ken Tyler

mailto://tylereng@pacbell.net

Post a reply to this message

Attachments:

Download 'blade.jpg' (7 KB)

Preview of image 'blade.jpg'

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

I always thought that would be a _real_ accomplishment of sword-modelers,

would be the accuarate representation of a Katana. Probably the type whose

edge and back of blade followed the radius of different circles would be

easiest. However, the blades are actually very complex shapes, and the fact

that the metal is not uniform throughout the blade but is purposly hardened

to different crystalline structures in different parts of the blade makes

for some quite beautiful, and very hard to procedurally model!, textures.

And let's not even THINK about doing a wapped handle accuratly,and as far as

the orbate tsuaba got........ *shudder*

Still - it is probably _the_ sword modellers ultimate challenge. Someday

when I have a few months spare time, I may start pulling textbooks on

Japanese sword smithing off the shelf a give it a whirl, but not today.

The image? Damn close in any case :) Best approximation of that style of

blade I've seen I think :)

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Charles Krause wrote:

>

> I always thought that would be a _real_ accomplishment of sword-modelers,

> would be the accuarate representation of a Katana. Probably the type whose

> edge and back of blade followed the radius of different circles would be

> easiest. However, the blades are actually very complex shapes, and the fact

> that the metal is not uniform throughout the blade but is purposly hardened

> to different crystalline structures in different parts of the blade makes

> for some quite beautiful, and very hard to procedurally model!, textures.

> And let's not even THINK about doing a wapped handle accuratly,and as far as

> the orbate tsuaba got........ *shudder*

>

> Still - it is probably _the_ sword modellers ultimate challenge. Someday

> when I have a few months spare time, I may start pulling textbooks on

> Japanese sword smithing off the shelf a give it a whirl, but not today.

>

> The image? Damn close in any case :) Best approximation of that style of

> blade I've seen I think :)

I have longed for the talent to accurately model an edged weapon. I have

a couple of small books on the subject, one for knives the other mostly

french cutlass and broad swords, and buy the occasional magazine off of

the rack when something catches my fancy.

The textures would be a bit of a challenge but I think I could master

that with little effort. What has had me stumped is how to hollow grind

a curving edge without leaving scratches of blemishes from the operation.

Some of the finest cutting blades in the world have what is called a hollow

grind above the cutting edge.

It forms a gully of sorts that is actually deeper than the majority of

the taped thickness of the bevel leading to the sharpened edge. The

advantage of the hollow grind for those curious to know is that when the

material that is being cut into passes the keen sharpened edge of the

cutting tool the material has a very smooth edge that adheres to the flat

smooth surface of the blade. This causes jerky or start and stop cutting

sessions and is a nuisance.

The hollow ground blade limits this by allowing the material to start to

heal back towards itself and then is quickly angled outward breaking its

suction like grip to the surface of the blade. This action gives much

smoother cutting through materials much thicker than the height of the

blade and serves as a self cleaning process as well. In consequence this

reduced build up of compounds that will foul the cutting operation leading

to successful cutting operation with a repeatability that is refreshing.

The hollow grind operation is relatively easy on the right machining

equipment and the odd scratch of two can be eliminated by buffing it out

on a buffing and polishing wheel. Pov csg operations are not quite as

forgiving in this regard and forming a uniform indent in a curved surface

is uniquely challenging. Added to that is the limitation of having no way

to polish out any blemishes left by csg operations as you would be capable

of in the real world.

I think that I will continue to evaluate my thoughts about this for a

while before thinking about thoughtfully attempting a well thought out

approach to this thought provoking yet stimulating little problem.

--

Ken Tyler

mailto://tylereng@pacbell.net

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Charles Krause wrote in message <370a0952.0@news.povray.org>...

>The image? Damn close in any case :) Best approximation of that style of

>blade I've seen I think :)

>

Thanks. I think the only way to do a katana blade accurately would

be to use something like sPatch to model it and uv-mapped material maps

to texture. If I need a highly detailed katana (the pic was medium-low

detail)

I may play with the idea.

Gail

*******************************************************************

* gsh### [at] monotix co co za * ERROR: COFFEE.COM not found *

* http://www.rucus.ru.ac.za/~gail/ * Insert cup and press any key *

*******************************************************************

My Software never has bugs, It just develops random features

******************************************************************* za * ERROR: COFFEE.COM not found *

* http://www.rucus.ru.ac.za/~gail/ * Insert cup and press any key *

*******************************************************************

My Software never has bugs, It just develops random features

*******************************************************************

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Hmm, i didn't realise your fashination for killing things... Now I see.. :-)

--

//Spider

[ spi### [at] bahnhof se ]-[ http://www.bahnhof.se/~spider/ ]

What I can do and what I could do, I just don't know anymore

"Marian"

By: "Sisters Of Mercy" se ]-[ http://www.bahnhof.se/~spider/ ]

What I can do and what I could do, I just don't know anymore

"Marian"

By: "Sisters Of Mercy"

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Well, you won the award. A great sword.

--

//Spider

[ spi### [at] bahnhof se ]-[ http://www.bahnhof.se/~spider/ ]

What I can do and what I could do, I just don't know anymore

"Marian"

By: "Sisters Of Mercy" se ]-[ http://www.bahnhof.se/~spider/ ]

What I can do and what I could do, I just don't know anymore

"Marian"

By: "Sisters Of Mercy"

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Spider wrote in message <370A65D0.7C4CF71D@bahnhof.se>...

>Hmm, i didn't realise your fashination for killing things... Now I see..

:-)

>

>

<grin> now you know.

Where did you say you lived.... <g>

Gail

*******************************************************************

* gsh### [at] monotix co co za * ERROR: COFFEE.COM not found *

* http://www.rucus.ru.ac.za/~gail/ * Insert cup and press any key *

*******************************************************************

My Software never has bugs, It just develops random features

******************************************************************* za * ERROR: COFFEE.COM not found *

* http://www.rucus.ru.ac.za/~gail/ * Insert cup and press any key *

*******************************************************************

My Software never has bugs, It just develops random features

*******************************************************************

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Boy doesn't it just put a real crimp in your day when sword doesn't come out of

your victim cleanly:-)

Ken wrote:

> Charles Krause wrote:

> >

> > I always thought that would be a _real_ accomplishment of sword-modelers,

> > would be the accuarate representation of a Katana. Probably the type whose

> > edge and back of blade followed the radius of different circles would be

> > easiest. However, the blades are actually very complex shapes, and the fact

> > that the metal is not uniform throughout the blade but is purposly hardened

> > to different crystalline structures in different parts of the blade makes

> > for some quite beautiful, and very hard to procedurally model!, textures.

> > And let's not even THINK about doing a wapped handle accuratly,and as far as

> > the orbate tsuaba got........ *shudder*

> >

> > Still - it is probably _the_ sword modellers ultimate challenge. Someday

> > when I have a few months spare time, I may start pulling textbooks on

> > Japanese sword smithing off the shelf a give it a whirl, but not today.

> >

> > The image? Damn close in any case :) Best approximation of that style of

> > blade I've seen I think :)

>

> I have longed for the talent to accurately model an edged weapon. I have

> a couple of small books on the subject, one for knives the other mostly

> french cutlass and broad swords, and buy the occasional magazine off of

> the rack when something catches my fancy.

> The textures would be a bit of a challenge but I think I could master

> that with little effort. What has had me stumped is how to hollow grind

> a curving edge without leaving scratches of blemishes from the operation.

> Some of the finest cutting blades in the world have what is called a hollow

> grind above the cutting edge.

> It forms a gully of sorts that is actually deeper than the majority of

> the taped thickness of the bevel leading to the sharpened edge. The

> advantage of the hollow grind for those curious to know is that when the

> material that is being cut into passes the keen sharpened edge of the

> cutting tool the material has a very smooth edge that adheres to the flat

> smooth surface of the blade. This causes jerky or start and stop cutting

> sessions and is a nuisance.

> The hollow ground blade limits this by allowing the material to start to

> heal back towards itself and then is quickly angled outward breaking its

> suction like grip to the surface of the blade. This action gives much

> smoother cutting through materials much thicker than the height of the

> blade and serves as a self cleaning process as well. In consequence this

> reduced build up of compounds that will foul the cutting operation leading

> to successful cutting operation with a repeatability that is refreshing.

> The hollow grind operation is relatively easy on the right machining

> equipment and the odd scratch of two can be eliminated by buffing it out

> on a buffing and polishing wheel. Pov csg operations are not quite as

> forgiving in this regard and forming a uniform indent in a curved surface

> is uniquely challenging. Added to that is the limitation of having no way

> to polish out any blemishes left by csg operations as you would be capable

> of in the real world.

>

> I think that I will continue to evaluate my thoughts about this for a

> while before thinking about thoughtfully attempting a well thought out

> approach to this thought provoking yet stimulating little problem.

>

> --

> Ken Tyler

>

> mailto://tylereng@pacbell.net

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Thomas Lake wrote in message <370B317C.F62CF3DA@home.com>...

>Boy doesn't it just put a real crimp in your day when sword doesn't come

out of

>your victim cleanly:-)

>

Yeah - that's why the steretypical 'killing stroke' with a Katana (and NOT

because of HIGHLANDER, thankyouverymuch, it has historical basis) is to just

lop off the head with a single stroke :P

:)

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

![]()