|

|

|

|

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

Invisible wrote:

> Damn, this puppy does even more than I thought! You can put a Windows

> installation CD in your CD drive, remote in to the server, and install

> Windows over the network even though there's nothing in the server's

> CD-ROM drive.

<Invisible> ... which is obviously impossible ... </Invisible>

;-)

--

Darren New, San Diego CA, USA (PST)

My fortune cookie said, "You will soon be

unable to read this, even at arm's length."

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

BTW guys have you read/heard news about the 5TB/sqr. inch HP tape

back-up? I hope it could be in production so it arrives to my country in

about 6 months-1 year aprox., but again the price... probably is about

1000 $us... :(

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

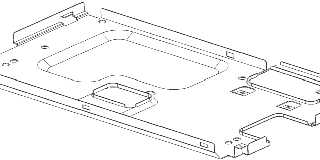

> Some pretty insane technical drawings happening in there! ;-)

>

> (I wonder how they do that BTW. Must be quite a challenge to draw

> something that complex...)

You don't draw it by hand, the CAD software will draw it based on the 3D CAD

data. You simply set the view mode to wireframe with hidden edges,

orthographic projection etc and then save as a PNG at whatever resolution

you desire. Takes about 30 seconds, see attached.

Actually making the 3D CAD data is not really a challenge, the software is

designed with drawing things like this in mind, so there are lots and lots

of features to make your life easy :-)

Post a reply to this message

Attachments:

Download 'image1.png' (19 KB)

Preview of image 'image1.png'

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

scott wrote:

>> Some pretty insane technical drawings happening in there! ;-)

>>

>> (I wonder how they do that BTW. Must be quite a challenge to draw

>> something that complex...)

>

> You don't draw it by hand

Well, not unless you're *insane* at least... ;-)

> the CAD software will draw it based on the 3D

> CAD data. You simply set the view mode to wireframe with hidden edges,

> orthographic projection etc and then save as a PNG at whatever

> resolution you desire. Takes about 30 seconds, see attached.

So... is something like this drawn from the real manufacturing data that

the plant uses? Or do they build specialised models simplified for

display purposes?

> Actually making the 3D CAD data is not really a challenge, the software

> is designed with drawing things like this in mind, so there are lots and

> lots of features to make your life easy :-)

I've often wondered how CAD manages to produce complex, detailed 3D

objects. I have yet to see a modeller that makes it feasible to produce

any moderately complex 3D shape. And yet, the world around me abounds

with intricately machined objects, so there must be somebody who knows

how to do it.

(Just sweeping my head from side to side right now, I see several CD

jewl cases, some external HD bays, an MP3 player which *could* be a

simple cube, but isn't, the casing of my computer... All of them have

pretty intricate shapes.)

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

scott wrote:

> see attached.

That's pretty mental, by the way. But what the hell *is* it??

Also... how do you make something like that? It looks like you'd either

have to mould it, or take a sheet of metal, bend it around a bit, cut

windows and drill holes in it...

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

> That's pretty mental, by the way. But what the hell *is* it??

A metal case that goes on the back of an LCD display. Mainly to avoid

electrical interference between the LCD and other parts in the car, but also

for mechanical protection. The pressed out lump in the centre is where

quite a few high components on the PCB are located, so it needs to provide

space for them, then there's two holes for connectors to go through, a

couple of features to make a good ground connection to the PCB, and various

clips and holes around the edge to securely fasten to the rest of the LCD.

Oh and of course some holes for screws to go through so the thing can be

fitted to the rest of the car!

> Also... how do you make something like that? It looks like you'd either

> have to mould it, or take a sheet of metal, bend it around a bit, cut

> windows and drill holes in it...

Yeh it's pressed metal, so you start with a blank sheet and then it goes

through a series of tools that bend and cut certain bits until the final

shape is produced (IIRC there's about 7 or 8 stages usually), no drilling -

the tools have sharp bits that cut the holes and other shapes, just like a

big hole-punch!

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

>> That's pretty mental, by the way. But what the hell *is* it??

>

> A metal case that goes on the back of an LCD display. Mainly to avoid

> electrical interference between the LCD and other parts in the car, but

> also for mechanical protection. The pressed out lump in the centre is

> where quite a few high components on the PCB are located, so it needs to

> provide space for them, then there's two holes for connectors to go

> through, a couple of features to make a good ground connection to the

> PCB, and various clips and holes around the edge to securely fasten to

> the rest of the LCD. Oh and of course some holes for screws to go

> through so the thing can be fitted to the rest of the car!

...it's times like this that I realise other people have way more

interesting jobs than I do! ;-)

> Yeh it's pressed metal, so you start with a blank sheet and then it goes

> through a series of tools that bend and cut certain bits until the final

> shape is produced (IIRC there's about 7 or 8 stages usually)

Damn. That process must take some designing!

> no drilling - the tools have sharp bits that cut the holes and other

> shapes, just like a big hole-punch!

Heh. How thick is the metal??

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

> I've often wondered how CAD manages to produce complex, detailed 3D

> objects. I have yet to see a modeller that makes it feasible to produce

> any moderately complex 3D shape.

Yes, but have you actually seen anyone using commercial CAD software like

Catia or Pro/Engineer? You know, the software that people who build planes

and cars use?

eg here is a screen shot of a model from Boeing:

http://www.nextcraft.com/media/aviation_technology/military_nasa/B737_catia_big.jpg

It's a bit more suited to doing this sort of stuff than a modeller like 3D

Studio or Blender. It is more focussed on dimensions and model hierarchy,

and less on the graphical appearance (most of the time you are just using

plane gourard shading or even wireframe if you need to see certain details).

For example, the modelling process in a CAD package for that metal case I

posted would be something like this:

- Draw the outline cuboid shape

- Add on extrusions and cuts for any bumps and dips

- Add rounds to any edges

- Shell the model (this leaves a shell of specified thickness, 2 clicks in

CAD)

- Add in holes where necessary

- Add more rounds

- Add in any clip geometry

The CAD software remembers all that history used to generate the model, so

you can always go back and change the shell thickness and everything else

updates (or move the position of a bump etc).

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

>> I've often wondered how CAD manages to produce complex, detailed 3D

>> objects. I have yet to see a modeller that makes it feasible to

>> produce any moderately complex 3D shape.

>

> Yes, but have you actually seen anyone using commercial CAD software

> like Catia or Pro/Engineer? You know, the software that people who build

> planes and cars use?

No. And that's what I've always wondered about - given the complexity of

the stuff these guys produce, their modelling tools must surely be more

sophisticated in some way.

> eg here is a screen shot of a model from Boeing:

>

> http://www.nextcraft.com/media/aviation_technology/military_nasa/B737_catia_big.jpg

OK, that's fairly crazy.

> For example, the modelling process in a CAD package for that metal case

> I posted would be something like this:

> - Draw the outline cuboid shape

> - Add on extrusions and cuts for any bumps and dips

> - Add rounds to any edges

> - Shell the model (this leaves a shell of specified thickness, 2 clicks

> in CAD)

> - Add in holes where necessary

> - Add more rounds

> - Add in any clip geometry

>

> The CAD software remembers all that history used to generate the model,

> so you can always go back and change the shell thickness and everything

> else updates (or move the position of a bump etc).

I'd almost consider trying to track down some software like this - if it

wasn't for the fact that I keep hearing that it costs a fortune and

crashes routinely...

Post a reply to this message

|

|

|  |

|  |

|

|

|

|

|  |

|  |

|

|

>> Yeh it's pressed metal, so you start with a blank sheet and then it goes

>> through a series of tools that bend and cut certain bits until the final

>> shape is produced (IIRC there's about 7 or 8 stages usually)

>

> Damn. That process must take some designing!

Yes, that's why the tools have ridiculous prices, usually with 6 or even

sometimes 7 figures! And then you realise why the guy gets annoyed when you

ask for +/-0.1mm tolerance between two specific points :-)

>> no drilling - the tools have sharp bits that cut the holes and other

>> shapes, just like a big hole-punch!

>

> Heh. How thick is the metal??

Usually 0.3 - 0.6 mm depending on how big it is. The tools are quite beefy

though, see attached (that is just stage 4 out of 7), all the intricate

detail in the middle is what actually makes the cuts and folds, the inner

working of each stage can be quite complex with spring loaded plates and

levers etc to do the bending correctly as the two halfs come together.

Post a reply to this message

Attachments:

Download 'image1.jpg' (29 KB)

Preview of image 'image1.jpg'

|

|

|  |

|  |

|

|

|

|

|  |

![]()