|

|

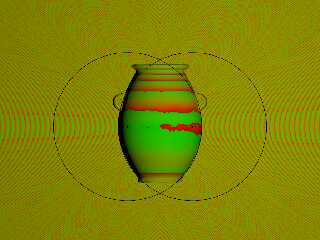

vase:

There are a few things that occurred to me, inspiring a few ideas to explore and

either confirm or refute their merit.

1. Given that there is all of this "sacred geometry" stuff that people go on

about, what is it's origin and why?

I think that we are taking a look at objects and structures that are designed

using a method much like we use CAD, however I think we can agree that the

ancients didn't have computers as we know them, and they probably used an

absolute measurement system different than our own.

But what makes absolute units irrelevant, and simultaneously preserves the

constants that we see?

Relative measurements. In geometry class, everything is laid out with a compass

and straightedge, and nothing is measured in "units". But everything is

measured in relation to line segment lengths, radii, etc.

The Greeks apparently got a lot of their knowledge from the Egyptians, and so

this comports with what we (think we) know about history.

2. If the designers used a well-developed system to lay out the design

parameters of objects and structures, and it was a relative system, then it

seems likely that they made use of all of the methods used in standard geometry.

Things would be laid out using arcs and lines and ratios. Pi would naturally

show up everywhere because ... circles.

3. Alex Dunn and Nick Sierra used a sphere in their metrological analysis - not

because they were trying to show that a sphere in any way "matched" the surface

of the vase, but more to show that the distance of the surface to the ideal

sphere was very constant along the vertical axis (among other reasons).

You showed that the overall vase shape deviates from an ellipsoid with your

overlay.

It occurred to me that if I was going to build a machine with a tooling guide

that was inspired by classical geometrical methods, then I'd use a lot of

circular arcs. Which led me to think that the vase might more strongly resemble

a vesica piscis, or when the circle centers do not lie on the the other circle,

what is called a geometrical lemon. This is also exactly the inner surface of a

spindle torus.

I've spent a lot of time developing some macros for use in fitting circles and

spheres to measured data sets, and coming up with a way to compare the vase to

the lemon shape. Fortunately, POV-Ray has some inbuilt functions and primitives

that ultimately make that task a lot simpler, and I was able to devise a 3D

texturing pattern that is essentially an unsigned distance function of the

lemon. By applying this pattern to the vase mesh, it maps the closeness of fit

of the mesh to the lemon.

The result is obviously sensitive to the radii of the generating torus, as well

as the vertical positioning of the pattern. I used the data from your recent

Twitter post to estimate the arc of the side of the vase, and using the chord

length and depth of that putative circle segment, calculated the radius of the

required circle. I used the vertical height of the maximal external radius of

the vase, since that made the most sense, in terms of the machining operation.

(I'm going to try to use the data points from scanning the vase to fit a circle

using the least-squares stuff, and see what happens with that)

****

And here's what's interesting: The curvature/shape of the vase seems to be

reasonably consistent with that below the handles, and only deviates above that.

Of course, that's as far as a tool traveling along a fixed arc could make it

before beginning to machine away the torus that would eventually give rise to

the handles. Also, the only significant deviation from that curvature is right

along the centerline of the two circles.

Owning a lathe myself, this would typically be the area that an operator is most

likely to accidentally come in contact with, either with a tool, the tool

support, or some other fixture or tool being moved in close proximity to the

spinning work.

4. I think it might be a prudent change of tactics to think about how the vase

would have been machined - the order of operations, and see if that inspires any

new ideas and areas of investigation.

Post a reply to this message

Attachments:

Download 'vaselemoncomparison.png' (1167 KB)

Preview of image 'vaselemoncomparison.png'

|

|

![]()